In today’s quickly evolving sectors, the demand for efficient, dependable, and adaptable heating solutions has increased dramatically. Flexible heaters are one type of technology that can address this demand. These heaters are transforming industries that demand precise temperature control, from electronics to aerospace, and their distinct features set them apart from standard heating solutions.

What Are Flexible Heaters

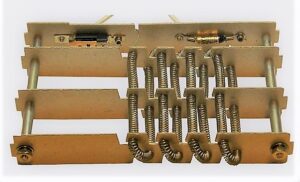

Flexible heaters are thin, lightweight heating elements that may be shaped and sized to fit a wide range of purposes. Flexible heaters, unlike rigid heaters, can operate on curved or irregular surfaces without sacrificing performance. Their adaptability enables them to operate in circumstances where traditional heaters would fail, such as high humidity, strong vibration, or extreme temperature extremes. These heaters are typically made of materials such as polyimide, silicone rubber, or polyester, which can withstand harsh working conditions while delivering efficient heat transfer. Flexible heaters are utilized in many industries, from medical devices to consumer electronics, all of which benefit from their dependability and adjustability.

Benefits and Applications

Flexible heaters are highly praised for their ability to distribute heat reliably across a large area while requiring minimal equipment. It makes them a fantastic alternative to current production processes that require high precision. The ability to integrate these heaters inside sensitive electronics, for example, guarantees that gadgets operate at the correct temperature without affecting performance or adding unnecessary weight. The aerospace and defense industries also rely on flexible heaters for a range of activities, including de-icing key components and guaranteeing the safe operation of sensitive equipment in harsh conditions. In industries where temperature control is critical, such as chemical manufacturing, these heaters offer an energy-efficient solution for preventing overheating and maintaining product quality.

Choosing the Right Manufacturer

When choosing flexible heaters, it is critical to engage with experienced manufacturers who understand the unique requirements of your application. The experience of the manufacturer can significantly influence the performance and lifetime of the heater, as not all heating systems are equal. An ideal manufacturer would not only provide a variety of customizable alternatives but will also advise you on material selection, watt density, and temperature range to ensure an excellent fit for your needs. This level of flexibility enables flexible heaters to succeed in industries that require precise temperature control and long-lasting performance in harsh environments. This is especially essential in industries that value sustainability, as flexible heaters can help cut energy usage while maintaining performance standards.

The Future of Flexible Heaters

As industries expand, so will the demand for innovative heating systems. Flexible heaters are projected to play a valuable part in emerging technologies such as electric vehicles, wearables, and smart homes. Manufacturers are constantly looking for new materials and manufacturing methods to meet the growing demand for these adaptable heaters, which are an essential component of modern engineering. Flexible heaters manufacturers offer a critical product that meets the diverse needs of various industries. Their capacity to deliver adaptable and energy-efficient heating solutions ensures their continued significance in current and emerging technologies. Whether for aerospace, medical, or consumer applications, flexible heaters are paving the way for breakthroughs that need precision, dependability, and adaptability in thermal management.