Are you noticing a significant build-up of byproducts as a result of a particular application? Are you now running out of storage space as national, state, and local regulatory requirements dictate that there must be specific steps to follow to ensure proper disposal? Have you been advised that the liquids, chemicals, and gases you are accumulating can be used to make other useful and valuable products but are unsure how? If yes, then here are two steps you should consider taking next.

Create a Safe, Efficient, and Effective Strategy

One of the first steps you should consider taking is to create a safe, efficient, and effective strategy to move the accumulated byproducts from one area to another for processing. You will need to design and engineer a piping pathway for these products to be mixed together safely at a compliant manufacturing facility.

Equipment and Materials

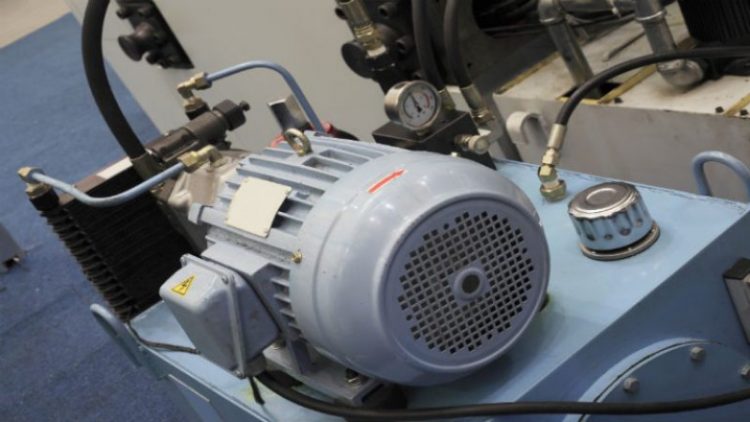

Another step you should take is to begin procuring all the necessary equipment and materials you will need to begin transferring the liquids, chemicals, and gases to convert them into valuable and highly useful products. This means you will need to also include piping to ensure the safety of your employees and the environment.

Who to Trust for Expert Assistance

Perhaps you are beginning to feel overwhelmed just devising a plan or strategy. You may now be searching for a company that can help with all aspects concerning process piping in New Jersey but are unsure how or where to start. When searching for a company that are experts in process piping in New Jersey, consider choosing a company that not only can provide the equipment and materials you will need but a company that also offers turnkey construction services. Choosing this type of company will provide you with an all-in-one solution to help you save time and save money.